Unveiling Best Practices in Industrial Electrical Design

In the dynamic landscape of industrial electrical design, incorporating best practices is paramount to ensure efficiency, safety, and optimal performance. This comprehensive guide explores the key strategies and methodologies that form the foundation of successful industrial electrical design.

Understanding the Importance of Industrial Electrical Design

Industrial electrical design serves as the backbone of manufacturing and automation processes. A meticulous approach not only enhances operational efficiency but also contributes to the longevity and reliability of electrical systems.

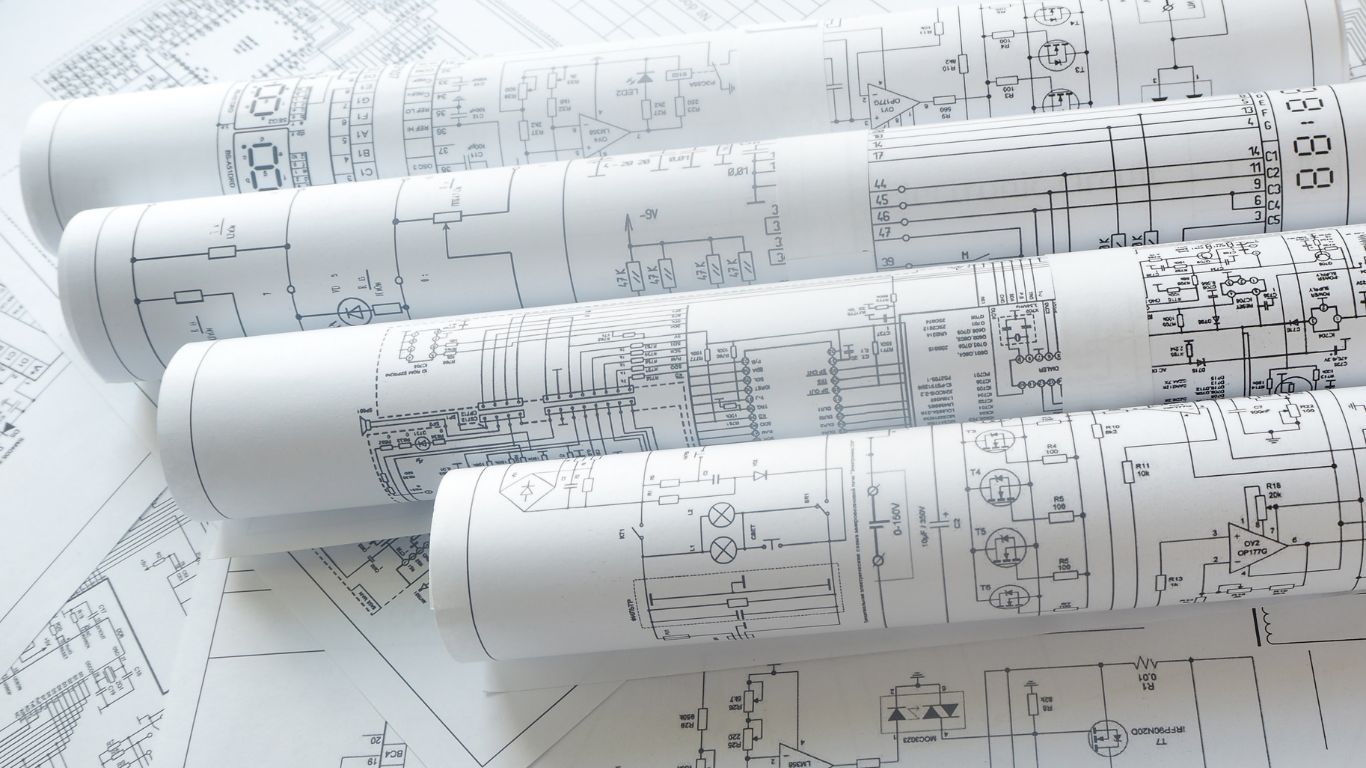

Preliminary Considerations for Industrial Electrical Design

Site Analysis and Layout:

Before diving into the design process, a thorough analysis of the industrial site is essential. Consider the layout, spatial constraints, and environmental factors that might impact electrical installations.

Load Analysis:

Conducting a comprehensive load analysis helps in determining the power requirements of different sections within the industrial setup. This forms the basis for sizing electrical components appropriately.

Designing Power Distribution Systems

Smart Sizing of Components:

Efficient power distribution begins with the proper sizing of components such as transformers, switchgear, and distribution panels. This prevents overloading and ensures a balanced distribution of power.

Redundancy Planning:

To mitigate the impact of equipment failure, incorporating redundancy in power distribution systems is critical. Redundant paths and backup systems guarantee uninterrupted power supply.

Integration of Renewable Energy:

Incorporating renewable energy sources like solar or wind can enhance the sustainability of industrial operations. This involves strategic integration into the overall electrical design.

Ensuring Safety through Effective Grounding

Grounding Systems:

A robust grounding system is fundamental for safety and equipment protection. Proper grounding minimizes the risk of electrical faults and ensures a safe path for fault currents.

Equipotential Bonding:

Connecting all exposed conductive parts to maintain the same electrical potential reduces the risk of electric shock and minimizes electromagnetic interference.

Implementing Best Practices in Control Systems

PLC Programming:

Efficient Programmable Logic Controller (PLC) programming is vital for controlling machinery and processes. Logical programming enhances system responsiveness and facilitates easier troubleshooting.

Industrial Communication Protocols:

Selecting appropriate communication protocols, such as Modbus or Profibus, ensures seamless data exchange between various components. This is crucial for real-time monitoring and control.

Incorporating Technological Advancements

IoT Integration:

The Internet of Things (IoT) has revolutionized industrial electrical design. Integrating IoT technologies allows for remote monitoring, predictive maintenance, and data-driven decision-making.

Advanced HMI Design:

Human-Machine Interface (HMI) design plays a pivotal role in user interaction. Intuitive interfaces enhance operator efficiency and contribute to a safer working environment.

Embracing Sustainability in Electrical Design

Energy-Efficient Lighting Systems:

Opting for energy-efficient lighting solutions, such as LED technology, reduces power consumption and contributes to sustainability goals.

Power Factor Correction:

Implementing power factor correction measures enhances energy efficiency, reduces losses, and often leads to cost savings in the long run.

Conclusion:

In the ever-evolving landscape of industrial electrical design, adherence to best practices is not just a recommendation but a necessity. This guide has unveiled the key considerations, from initial site analysis to embracing technological advancements, to empower professionals in creating robust and future-ready electrical systems. By adopting these best practices, industries can not only meet current operational needs but also lay the groundwork for sustainable and innovative advancements in the years to come.

Ready to Transform Your Electrical Designs? Don’t let the intricacies of industrial electrical design overwhelm you. Focus on what you do best, and let the experts at RemoteTechHub handle the complexities of design. Our seasoned professionals are ready to craft bespoke electrical solutions tailored to your unique needs. Request a quote today and elevate your industrial operations with precision and efficiency. Your vision, our expertise – a powerful partnership for success.