CNC and Laser Cutting programming

At the forefront of precision, our CNC Programming and Laser Cutting Programming services seamlessly bridge the realms of 2D and 3D design. For CNC Programming, whether you present intricate 2D designs or detailed 3D models, we specialize in translating your vision into CNC code, meticulously programming machinery for exact manufacturing. Simultaneously, our Laser Cutting Programming services, tailored to transform your designs into cutting-edge programs, ensure that every cut, contour, and operation is meticulously guided by laser-ready code. Our commitment to precision in manufacturing extends across both services, where every detail is etched with expertise and excellence, defining a new standard in accurate and efficient production. Elevate your manufacturing process with our comprehensive solutions that drive precision from concept to creation.

Services Offered:

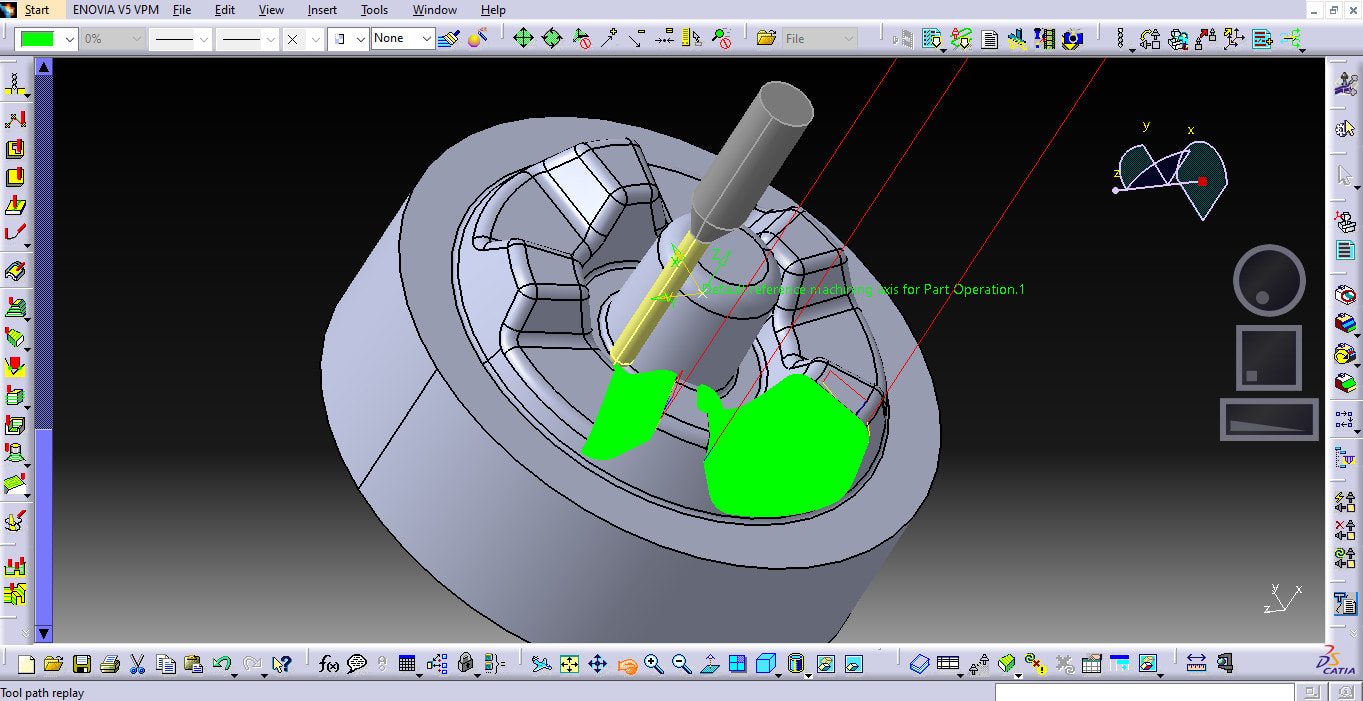

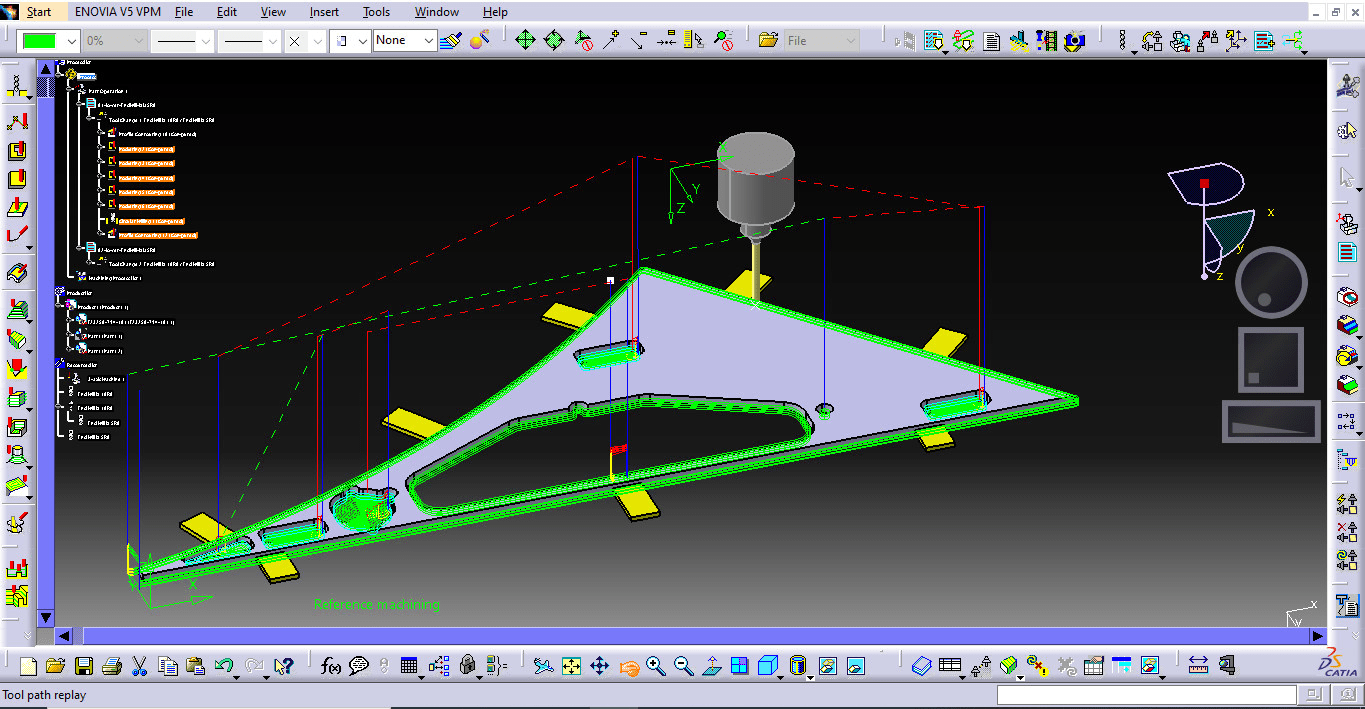

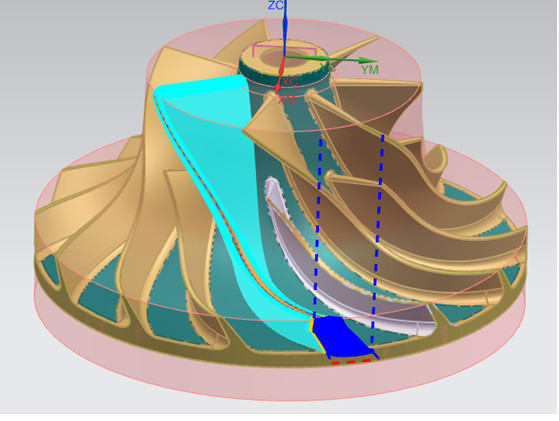

CNC Programming

Harness the power of precision in manufacturing with our CNC Programming services. Whether you present intricate 2D designs or detailed 3D models, we specialize in translating your vision into CNC code. Meticulously programming machinery, we ensure every cut, contour, and operation aligns with your design, elevating the accuracy and efficiency of your manufacturing process.

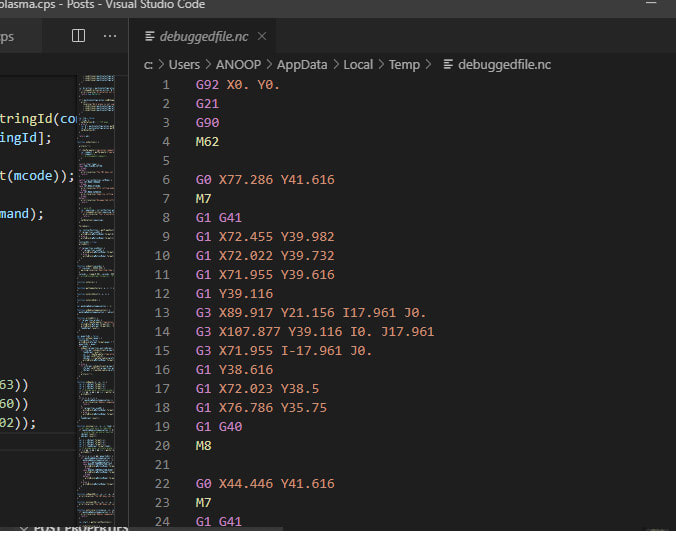

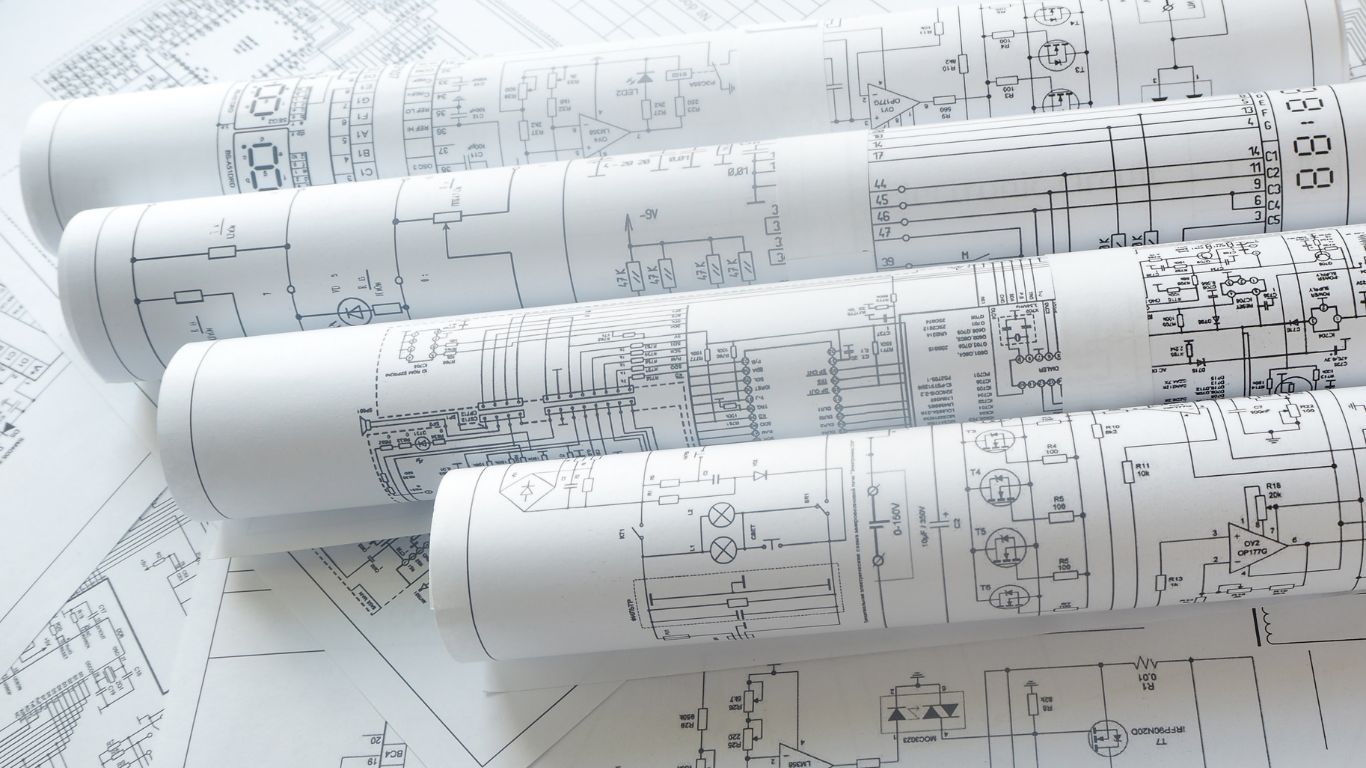

Laser Cutting Programming

Dive into the realm of precision with our Laser Cutting Programming services. Crafted to transform your designs into cutting-edge programs, we excel in generating laser-ready code that guides the precision of the laser cutting process. Each cut, contour, and operation is meticulously programmed, ensuring your creations come to life with the characteristic accuracy and efficiency of laser technology.

Comprehensive Code Generation

Experience the synergy of CNC and laser cutting code generation with our comprehensive service. From intricate 2D designs to detailed 3D models, we seamlessly provide the code needed for both CNC and laser cutting processes. Our commitment to precision manufacturing ensures that every detail in your designs is translated into accurate and efficient code, defining a new standard in manufacturing excellence.

Happy Clients

Our Process:

Consultation and Analysis:

Begin by filling out our website contact form. Provide an overview of your project, attaching any relevant hand-drawn schematics or specifying your requirements.

Upon receiving your form submission, we’ll carefully review the information and follow up with any clarifying questions or additional details we may need. This step ensures a comprehensive understanding of your project objectives.

Quote, Agreement & Payment:

Based on the information provided, we will prepare a detailed quote for the scope of work. Once you’re satisfied with the terms, we’ll proceed to formalize the agreement. Expect to receive the agreement link through your email address.

After confirming the agreement, you’ll receive a secure payment link through your email address. This allows for a streamlined and secure transaction process, providing convenience and peace of mind.

Commencement of Work: Client Review, Feedback, and Revisions:

Upon receipt of the agreed-upon payment, our team will commence the drawing of schematics, updating files, or conducting power calculations, depending on your project requirements.

As drafts are prepared, we’ll share them with you for review and feedback. This collaborative process ensures that the work aligns with your expectations. Feel free to provide comments or request revisions through email communication.

Finalization and Delivery: Post-Service Support:

Once all revisions are incorporated and the work meets your approval, we will finalize the designs and calculations. You will receive the completed project package via email, ready for implementation.

Even after project completion, our commitment to communication continues. If you have any questions or require additional support, reach out to us through our website contact form.